Difference between revisions of "Flush-Form CoreXY Design"

Poofjunior (talk | contribs) |

Poofjunior (talk | contribs) |

||

| Line 4: | Line 4: | ||

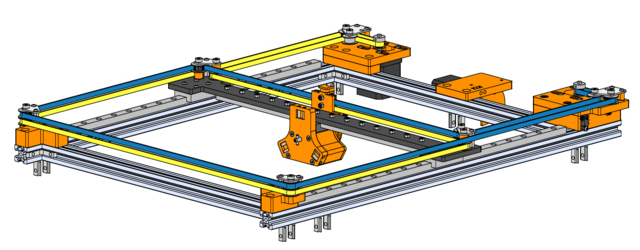

I'd like to add one more CoreXY variant to the mix, which I'm calling the 'Flush-Form CoreXY'. | I'd like to add one more CoreXY variant to the mix, which I'm calling the 'Flush-Form CoreXY'. | ||

| − | [[File:Flush-form CoreXY.png| | + | [[File:Flush-form CoreXY.png|center|640px]] |

| − | This stylize pattern actually creates a few conveniences. | + | This stylize pattern actually creates a few conveniences. First, it makes the belts easier to assemble as the two patterns closely mirror each other. If this is your first CoreXY, stringing the belts can be somewhat cumbersome--especially if you are not the designer. Second, by stacking the belts that meet at the carriage, it eliminates any torisional loads placed on the carriage that would cause an overconstrained carriage to wiggle back-and-forth each time it changed direction. Next, it exposes easy belt tensioning, by mounting both motors into slots and enabling their setpoin to be adjusted with a side-mounted set screw. Finally, it's quite pleasing to the eye. |

Revision as of 20:59, 25 September 2019

The original CoreXY platform was a reimagined belt pattern for lightweight XY gantries at higher speeds than their typical cartesian cousins. By mounting both motors on the frame in an "Etch-a-Sketch"-like fashion, the design reduces the moving mass by one motor while still enabling translation in an XY plane.

Over the years, the CoreXY has seen many, many belt pattern tweaks, most of which offer minor conveniences, some of which even have their own names, like the Fabtotum-style belt pattern.

I'd like to add one more CoreXY variant to the mix, which I'm calling the 'Flush-Form CoreXY'.

This stylize pattern actually creates a few conveniences. First, it makes the belts easier to assemble as the two patterns closely mirror each other. If this is your first CoreXY, stringing the belts can be somewhat cumbersome--especially if you are not the designer. Second, by stacking the belts that meet at the carriage, it eliminates any torisional loads placed on the carriage that would cause an overconstrained carriage to wiggle back-and-forth each time it changed direction. Next, it exposes easy belt tensioning, by mounting both motors into slots and enabling their setpoin to be adjusted with a side-mounted set screw. Finally, it's quite pleasing to the eye.